Direct Drive Vs Belt Drive Wheel

Feedback through the wheel, maybe, arguably, closer to the real car depending on the game and effects included. It wouldn’t make much strategic sense to launch 2 competing products so close together.

While belt drive turntables are incredibly popular, they have a lower torque than direct drive turntables.

Direct drive vs belt drive wheel. Direct drive vs idler drive vs. Check out my gear on kit: Belt drive turntables also have a slightly less accurate playback speed than direct drive turntables.

So with requirements being less stringent, other drives such as idler or belt might be equally valid. Check out our accuforce direct drive steering wheel ecosystem here: Its an electric motor that directly drives the steering shaft.

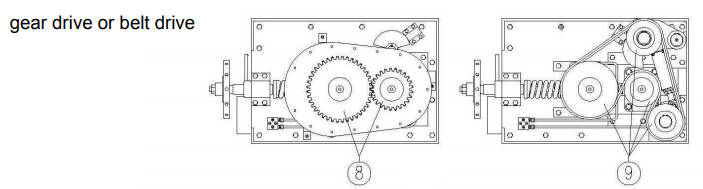

So, as years pass by the efficiency gradually decreases a little bit. Moreover, it is always kept under full lubrication. The gear and belt driven wheels have a chain of gears and belts that take a lot of the fidelity out of the feel from the motor.

In general, belt drives provide better torque than hub systems of the same price. Direct drive wheels can deliver higher peak and nominal (holding) torque levels. Benefits the clearest benefits to direct drive systems seem obvious as soon as you look at them.

A shaft driven system will also give a more direct connection between the driver’s foot and the rotation of the wheels. In addition, some people like to get more creativity in the department by getting ideas through their settings and belt drives. With the servomotor connected directly to the motor shaft, the driving sensation is.

Which is the right path? Loss of power due to friction. We think that we may see a clubsport direct drive wheel in the future, but not as soon as you think.

Disadvantages of belt drive over direct drive: Once this platter gets up to speed, the odds of it having micro changes in pitch are virtually nil. In others, they are connected using an.

No tolerance to variation of load. The other a revolver, nothing special at all, heard many belt drives, none had. The wear and tear of belt is inevitable.

Direct drives seem to benefit from advantages of both belt systems and hub systems, while minimizing the disadvantages from either. Engineers and designers commonly use electric motors to power hydraulic pumps. We already know the direc.

Only owned two belt drives, a transrotor based diy tt, transrotor bearing and platter and origin live motor in a very heavy pod with spikes , free standing, ok but just didn't do it for me. Belt drive is best suited to budget force feedback steering systems while direct drive is better suited to the high end wheel market where realism and accurate detail reproduction is required. This also allows for more wheel selection exchanges.

What this means for sim racers is that they are now directly connected to the motor of the wheelbase, meaning that everything that is being translated into force feedback from our sim, gets translated 1:1 to us as a driver. It can be avoided if you replace the belt frequently (once in 5 years) high noise due to wearing of the belt. Whereas a belt driven cvt system might lag for a second to engage the clutches, a shaft drive will transmit that energy directly to the drive shaft and wheels.

We discuss positives and negatives for eac. Over time, a belt drive may need to be replaced. They also allow the use of full length plate wheels instead of thin pu sleeve hub motors.

On the other hand, belt drive is one friction drive and has surface contact between pulley and belt (lower pair). A direct drive wheel, on the other hand, uses an industrial servomotor that is attached directly to the steering wheel. In theory direct drive is better in terms of delay between event in sim and ffb at the wheel, and the engine torque is applied directly to the wheel, rather than passing through a belt, so it's possible to control with more precision and consistency.

Direct drive gives you instant and a lot more torque than anything else can. Thus gear drive provides high efficiency, usually above 99%. The short answer is that it depends on what kind of listening you do, how much you need isolation from feedback, and how much you are willing to spend.

The direct drive wheel difference is right in its name. Which they are imho because they are perfectly able to provide constant and accurate speed which is all you need. Most notably, direct drives allow the use of full ‘thane wheels.

Dds are no better in that respect, at least from what below (audio magazine) measurements can tell. In some cases, the motor and pump are set up in a direct drive configuration.

Posting Komentar untuk "Direct Drive Vs Belt Drive Wheel"